Prototypes are one or several function models or samples that are made according to the product appearance drawing or structure drawing without opening the mold, which is used to check the rationality of appearance or structure. The prototype is also called the first board in different places.

Why we use prototype?

Usually, the products that have just been developed or designed need to be handmade. The handcraft is the first step to verify the feasibility of the products, and is the most direct and effective way to find out the defects, deficiencies and drawbacks of the designed products, so as to improve the defects pertinently, until the deficiencies can not be found from individual samples. At this point, it is usually necessary to carry out small batch trial production, and then find out the deficiencies in the batch to improve. Generally, the finished products can not be perfect or even can not be used. Once there are defects in direct production, all products will be scrapped, which greatly wastes manpower and material resources and time. However, the handcraft is generally a small number of samples, with short production cycle and less labor and material resources. It can quickly find out the shortcomings of product design and then improve it, so as to provide sufficient basis for product finalization and mass production.

(1) . verify design The prototype is not only visible, but also can be touched. It can reflect the designer's creativity intuitively in the form of physical objects, avoiding the disadvantages of "drawing well and making bad". Therefore, the production of handcraft is essential in the process of new product development and product shape refinement.

(2) . inspection of structural design Because the handboard can be assembled, it can directly reflect the rationality of the structure and the difficulty of installation. It is easy to find and solve problems as soon as possible.

(3) . reduce the risk of direct die opening Due to the high cost of mold manufacturing, the relatively large mold is worth hundreds of thousands or even millions. If the unreasonable structure or other problems are found in the process of opening the mold, the loss can be imagined. However, prototype production can avoid this kind of loss and reduce the risk of mold opening.

(4) . products will be displayed in advance Because of the advanced nature of prototype production, you can use the prototype to publicize the products before the mold is developed, and even prepare for the sales and production in the early stage, so as to occupy the market as soon as possible.

Application of Prototypes:

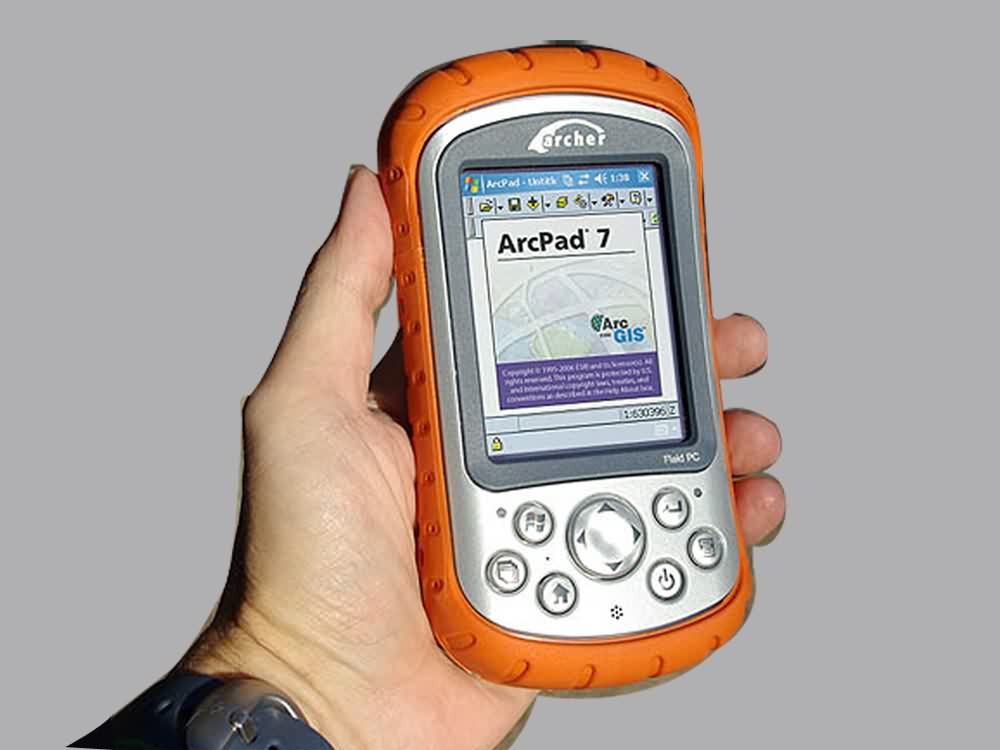

(1) . Electronic appliances Display, humidifier, juice machine, vacuum cleaner, air conditioning panel.

(2) . Toy animation Cartoon characters, animation peripheral products, miniature car model, aircraft model.

(3) . Medical cosmetology Medical equipment, beauty tools, nail tools, fitness equipment.

(4) Aircraft model military industry Protective mask, high precision machining products, etc.

(5) . Bank security Cash register, ATM, tax control machine, tachometer, 3G camera.

(6) . automobile transportation Car lights, bumpers, seats, electric cars.

(7) . Building Exhibition Building model, concept building, exhibition hall layout and display pattern.

(8) . Craft accessories PMMA crafts, relief crafts, ornaments, antique utensils.

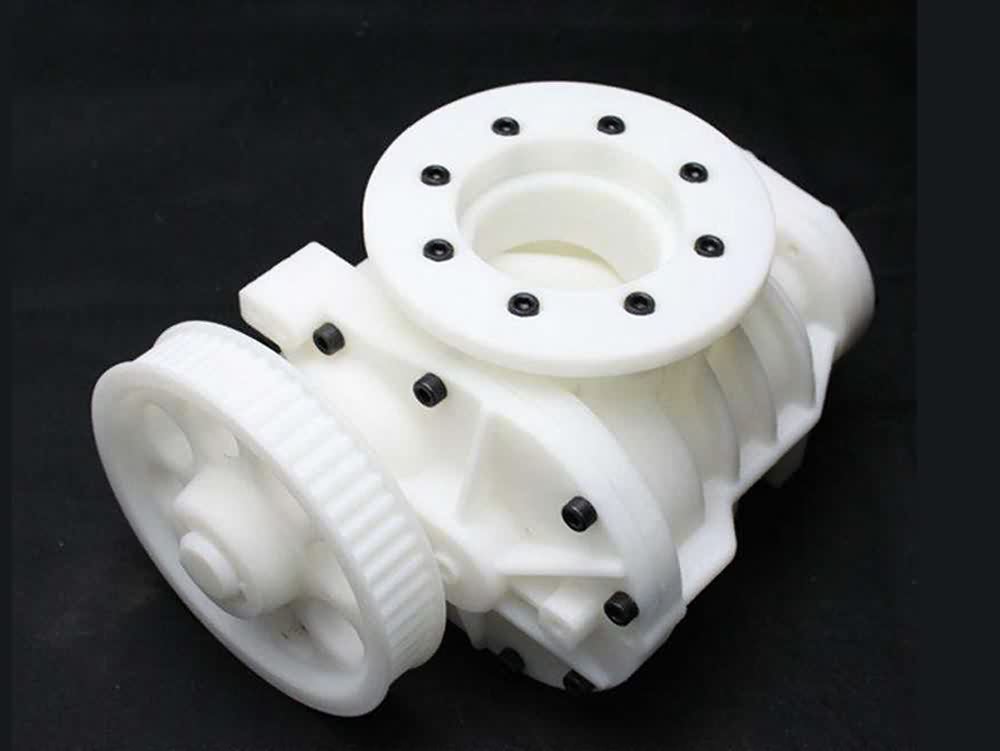

CNC plastic prototype

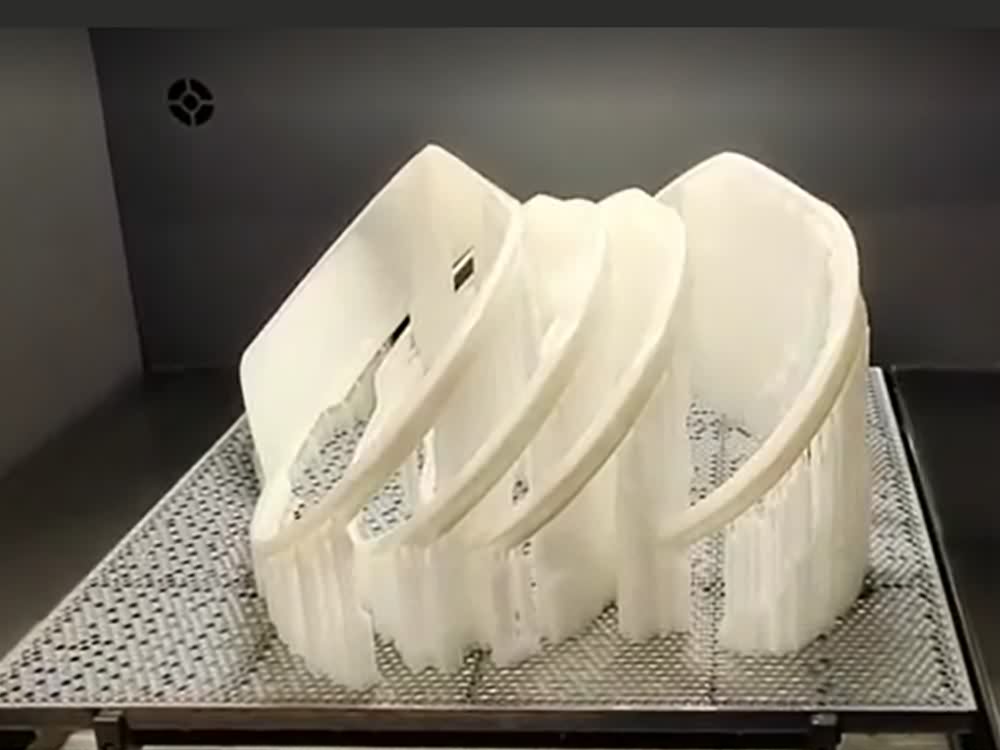

SLA plastic prototype

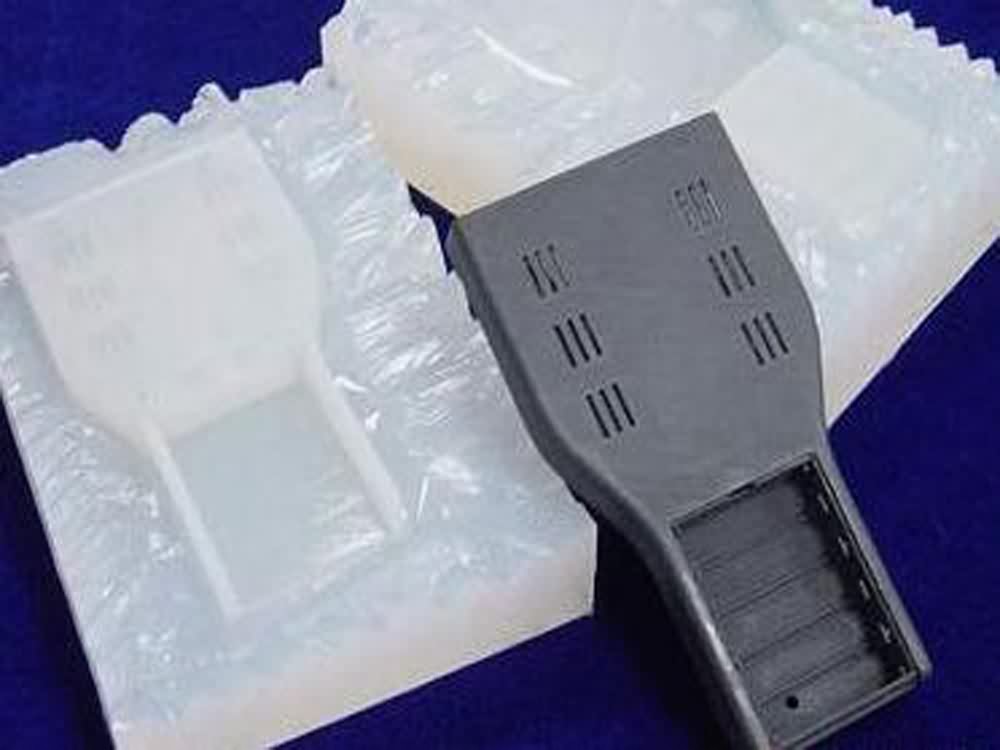

vacuum molding prototypes

Transparent plastic parts

Plastic housing prototype for electronic appliances

Plastic housing prototype for home appliance

Plastic prototypes for automobile

Prototype for power tool

Silicone prototypes

Prototype model

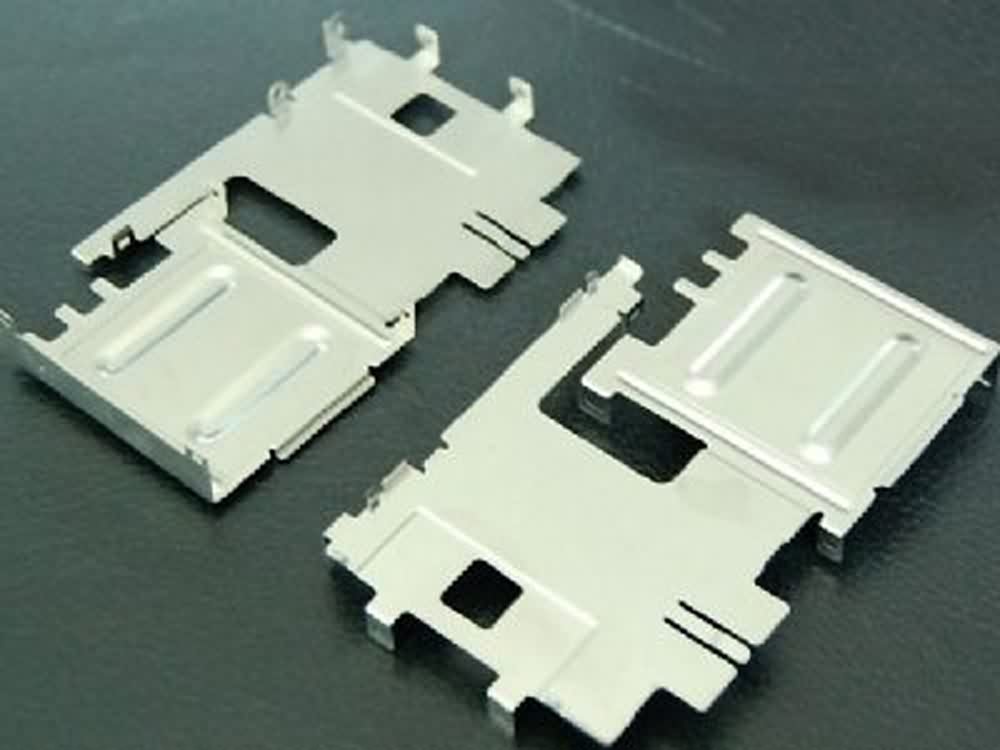

Stamped sheet metal prototype

CNC metal prototype

Aluminium prototype

Stainless steel prototype

Metal 3D printing prototypes

Prototype classification

1. According to the means of production, the prototype can be divided into manual prototype and numerical control prototype

(1) Handcraft: the main workload is done by hand. Hand made prototype is divided into ABS prototype and clay prototype

(2) CNC prototype: the main workload is completed by CNC machine tools, and according to the different equipment used, it can be divided into laser rapid prototyping (SLA) and machining center (CNC) and RP (3D printing).

A: RP prototype: it is mainly produced by 3D printing technology. Laser rapid prototyping is commonly known as SLA prototype, but laser rapid prototyping is one of 3D printing.

B: CNC prototype: it is mainly produced by the processing center.

Compared with CNC, RP has its own advantages The advantages of RP prototype are mainly manifested in its rapidity, but it is mainly formed by stacking technology. Therefore, the RP prototype is generally relatively rough and has certain requirements on the wall thickness of the product, for example, if the wall thickness is too thin, it can not be produced. The advantage of CNC prototype is that it can reflect the information expressed in the drawing very accurately, and the surface quality of CNC prototype is high, especially after the surface spraying and silk screen printing are completed, even more brilliant than the products produced after opening the mold. Therefore, CNC prototype manufacturing has become the mainstream of the industry.

Mestech provides customers with prototype making services for your new products , such as the processing and manufacturing of plastic and metal prototypes for electronic products, electrical products, medical products, auto parts and lamps, and so on. If you need, please contact us.