As a professional manufacturing enterprise, MESTECH not only provide products, but also provide all-round technical solutions and services. These services include plastic products, hardware products mold design and production, parts molding, post-processing, product design and assembly, export customs declaration and other aspects.

Mould making and injection molding

MESTECH has a complete plastic mold manufacturing system. More than 300 pairs of plastic moulds were manufactured in a year, and the injection molding and post-processing of plastic products were undertaken. The standard of the mould is HASCO, DEM, MISUMI and CHINA. In addition to meeting customers in this region, our molds are also exported to Europe, North America and Asia and other countries and regions.

(Read more)

Metal parts processing

Solid metals have higher melting point, hardness and strength, conductivity, ductility and metallic luster than other materials. By adjusting the internal composition and molecular structure of metals, we can obtain properties far superior to those of plastics and other nonmetals

Excellent metal alloy and high precision parts can be obtained. Therefore, metal parts are widely used in machinery and equipment, chemical industry, aviation, aerospace, navigation, transportation, lighting, medical treatment and electrical.

The commonly used metals are steel, aluminum alloy, zinc alloy, copper, copper alloy and titanium alloy. The processing methods of the parts made of them are different because of their different structures, compositions and uses. In addition to metal smelting, the main processing technologies we use to obtain the final size and shape of metals are: die casting, powder sintering and machining.

(Read more)

Products design

A perfect product surely comes from excellent design first.

With the development of Internet technology and the emergence of new product technology, the update of new products in today's market is faster and faster. How to let your products enter the market in the shortest time is the key to the competitiveness of enterprises. Many companies usually entrust external resources to complete some or most of the product design work, in order to shorten the product development cycle, and focus on market operation and core things.

Mestech engineers can provide plastic parts, hardware parts and product structure design, feasibility analysis, as well as follow-up mold manufacturing, parts manufacturing and finished product assembly services according to customers' product requirements.

(Read more)

Prototype making

A new product from the beginning of design to production and marketing, often need to invest a lot of money, energy and time. The quality of product design directly determines the success of the product. Prototype is an important means to test product design. It is used to check the problems existing in product design, improve the design, and avoid major mistakes that lead to major losses in the later stage. For example, for automobiles, airplanes, ships and electronic and electrical products, the prototypes are always made for verification before formal manufacturing of molds and parts.

Mestech is able to provide customers with CNC, 3D printing of plastic parts and metal parts as well as handmade model production of SLA, as well as small batch sample production.

(Read more)

Products assembly

There are thousands of products on the market, which are constantly updated everyday. The competition in the market is increasingly fierce. Companies vary in size. Many companies, limited by their own business feature, they focus on the design and development of market or new technology products, and do not set up their own product assembly plants.

We can provide product assembly and technical support for such customers. It includes a series of one-stop services such as product design, parts production, procurement and assembly.

(Read more)

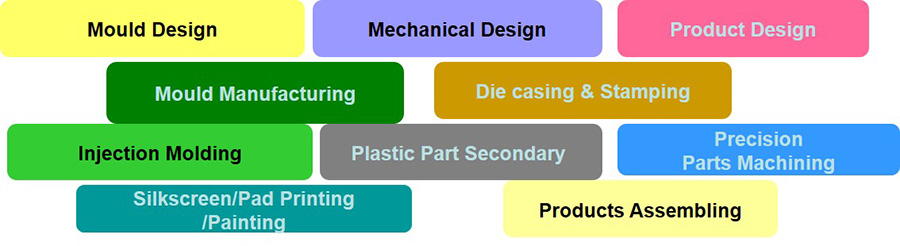

Services we offer

To provide high-quality services and products of plastic molding, metal die-casting and machining is one of MESTECH 's main objectives. With our excellent equipment and facilities, we also have a team of experienced engineers and skilled staffs. We guarantee the quality of our products and services through the continuous improvement of advanced technology and technique, as well as strict organization and management.

Product manufacturing always consist of a series of related chains. In order to meet the developing needs of customers, we provide turnkey services from initial design, development, manufacture to product assembly. You can find out more about each below or alternatively, contact us to discuss your requirements.